Slim Bearings

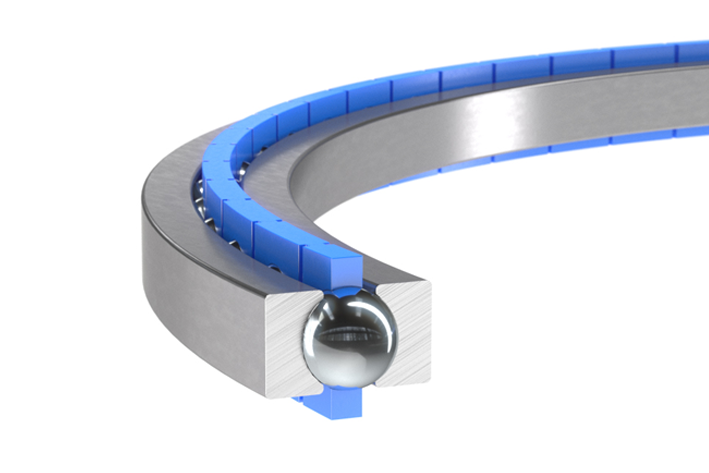

Franke slim bearings deliver a convincingly smooth run, require an extremely compact mounting space and are simple to assemble. Slim bearings consist of one inner and one outer race ring with hardened and profiled raceways and a plastic cage with retained balls. The rolling elements touch the race rings at two points each, hence ensuring the 4-point system. The race rings are separated; their diameter can therefore be altered elastically for mounting.

Bearing Type

• 2 Race rings with profiled raceways

• Plastic cage with retained balls

• Franke slim bearings of type LSA deliver a convincingly smooth run, require extremely compact mounting space, ensure simple assembly and come at a favorable price.

Characteristics

• Simple, compact integration, LSA, infinitely variable Ø range

• Cost-effective alternative to standard slim bearings

• Not preloaded bearings

• Slim bearings type LSA consist of one inner and one outer race ring with hardened and profiled raceway and a plastic cage with retained balls. The rolling elements touch the race rings at two points each, hence ensuring the 4-point system. The race rings are separated; their diameter can therefore be altered elastically for mounting.

Diameter Range

• Infinitely variable from 4″ to 30″

Mating Structure

Slim bearings type LSA consist of one inner and one outer race ring with hardened and profiled raceway and a plastic cage with retained balls. The rolling elements touch the race rings at two points each, hence ensuring the 4-point system. The race rings are separated; their diameter can therefore be altered elastically for mounting.

Material:

Race rings: 54SiCr6,

Rolling element: 100Cr6,

Cage: PA12

Operating temperature:

-20 °C to +80 °C, short-term up to +100 °C

Peripheral speed:

Max. 5 m/s, without seal max. 10 m/s

Lubricant:

Shell Gadus S3 V220 C2

EXPERIENCE

With a collective knowledge and experience of over 30 years in engineering industry, we work to adapt, create and innovate, to enable us to deliver bespoke engineering solutions to meet your requirements.

DESIGN, MANUFACTURE, STOCK & SUPPLY

From our Lancashire headquarters we offer a one stop shop for all your linear and rotary requirements for both existing applications and new product innovations.

SITE ASSESSMENT, INSTALLATION & FITTING

As a privately owned business we have the flexibility to offer an industry unique full turnkey package to engineers. From site assessment, installation through to fitting.

Contact us

For more information or a no obligation quote please get in touch below.