Rotary Tables

Rotary Tables from global leaders Frankeare ready to install and perfectly suited to a vast list of applications. Franke LTA rotary tables in sizes LTA100 & LTA200 deliver excellent radial & axial run accuracy & well suited to high dynamic handling & assembly applications.

Contact UsTypes of Bearing Elements

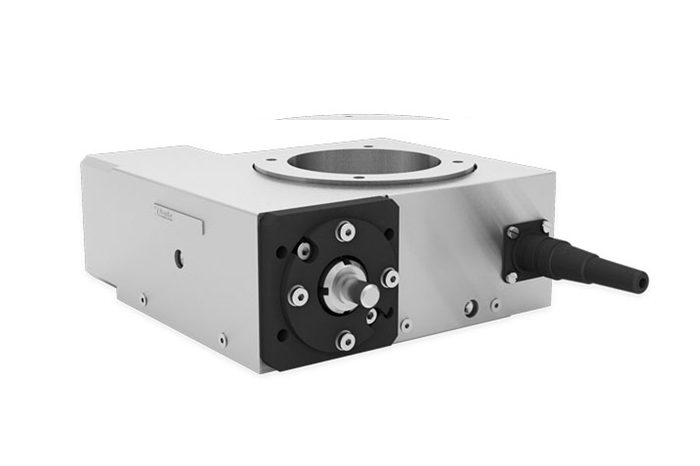

LTA Rotary Table

• Ready to install, perfectly suited for processing and handling applications

Characteristics

• Rotary table for highly precise handling applications

• Complete with motor and CNC-control unit (optional)

• Franke rotary tables of type LTA are lightweight, compact, ready-to-use positioning units. They are highly resilient and deliver outstanding radial and axial run accuracy. Franke rotary tables type LTA are versatile in use and are well-suited to light processing applications and also for dynamic handling and assembly applications.

Diameter Range

100 and 200mm

Material

Baseplate: Aluminium

Housing: V2A

Ball race rings: 54SiCr6

Rolling elements: 100Cr6

Worm wheel: wear-resistant bronze alloy

Worm shaft: CK45N hardened and ground

Accuracies

Radial and axial runout accuracies: LTA100: 30 μm LTA200: 30 μm

Positioning accuracy in arc seconds : LTA100:160 sec LTA200:120 sec

Repeatability in arc seconds: LTA100: 20 sec LTA200: 14 sec

Technical Details

Reduction ratio: 18:1 (LTA100), 36:1 (LTA200)

Temperature in use: –10 °C to +80 °C

Rotational speed: max. 100 min -1

Mounting position: any, but we recommend positions in which the drive module occupies the lowest point

Lubrication: with bearing grease via grease nipples

Optional: inductive proximity switch, flange/coupling to mount the motor, motorisation

For additional information on bearing selection, calculation, mounting and setting in please contact us

LTB Rotary Table

• Ready to install, perfectly suited for high precision movement

Characteristics

• Rotary table for high precision movement and measuring

• Complete with motor and CNC-control unit (optional)

• Franke rotary tables of type LTB are open-center, ready-to- use positioning units. They are highly resilient, lightweight (aluminium housing) and deliver outstanding ATR accuracy and discrimination. Franke rotary tables of type LTB are versatile in use and are primarily suited to movement and positioning tasks in the fields of measurement, testing and orientation.

Diameter Range

Graded from 125-400mm

Material

Housing : Aluminum corrugated

Ball race rings: 54SiCr6

Rolling elements: 100Cr6

Worm wheel: wear-resistant bronze alloy

Worm shaft: CK45N hardened and ground

Accuracies

Radial and axial runout accurancy: LTB125: 20 μm LTB175: 20 μm LTB265: 20 μm

LTB400: 30 μm

Positioning accuracy in arc seconds: LTB125: 80 sec LTB175: 80 sec LTB265: 70 sec LTB400: 50 sec

Repeatability in arc seconds: LTB125: 16 sec LTB175: 14 sec LTB265: 10 sec

LTB400: 8 sec

Technical Details

Reduction ratio: 360:1

Temperature in use: –10 °C to +80 °C

Rotational speed: max. 7 min -1

Mounting position: any

Lubrication: with bearing grease via grease nipples

Optional: inductive proximity switch, flnage/coupling to mount the motor, motorisation

For additional information on bearing selection, calculation, mounting and setting in please contact us

Contact us

For more information or a no obligation quote please get in touch below.

EXPERIENCE

With a collective knowledge and experience of over 30 years in engineering industry, we work to adapt, create and innovate, to enable us to deliver bespoke engineering solutions to meet your requirements.

DESIGN, MANUFACTURE, STOCK & SUPPLY

From our Lancashire headquarters we offer a one stop shop for all your linear and rotary requirements for both existing applications and new product innovations.

SITE ASSESSMENT, INSTALLATION & FITTING

As a privately owned business we have the flexibility to offer an industry unique full turnkey package to engineers. From site assessment, installation through to fitting.