LER Technical Information

Product type

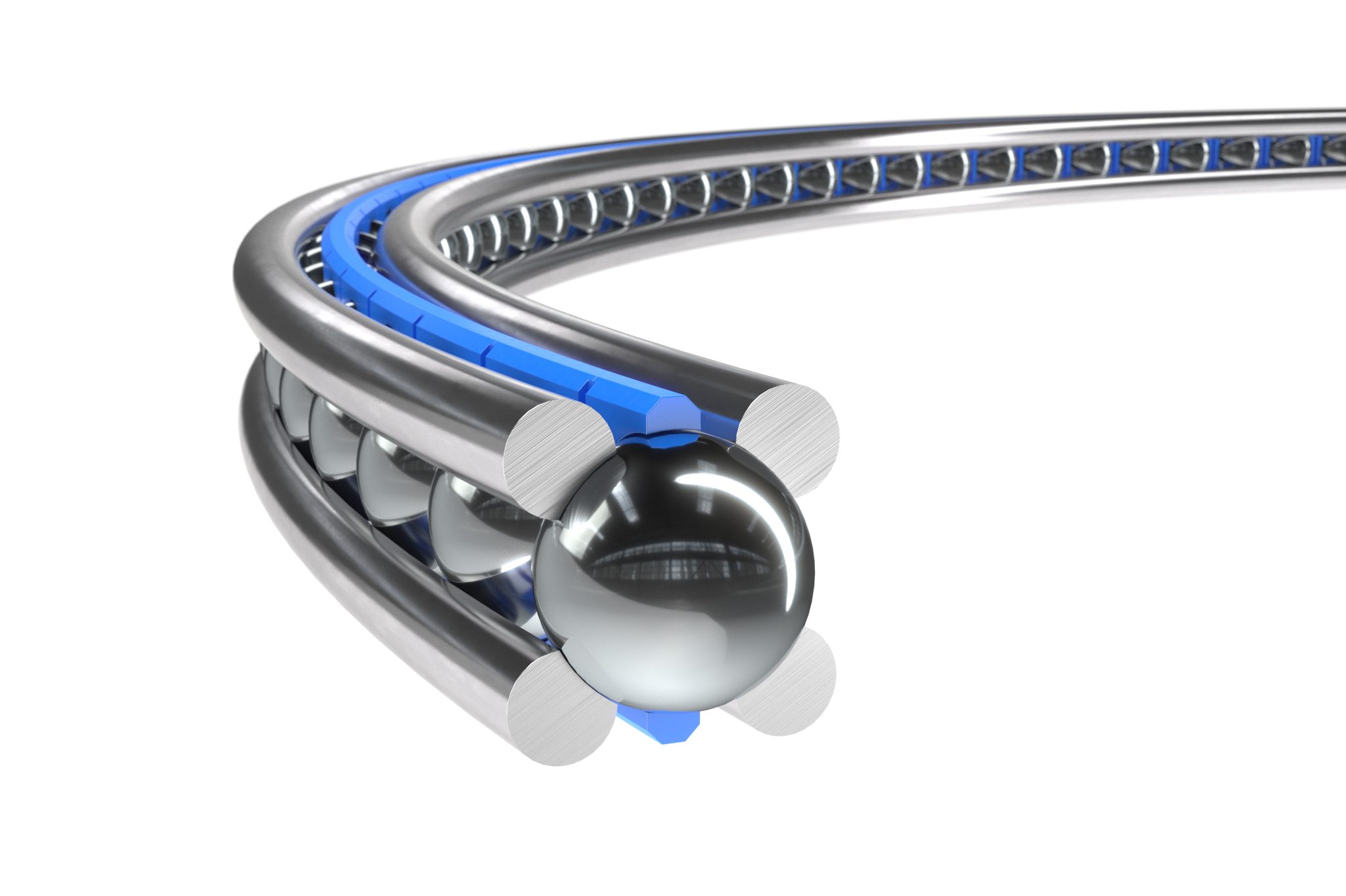

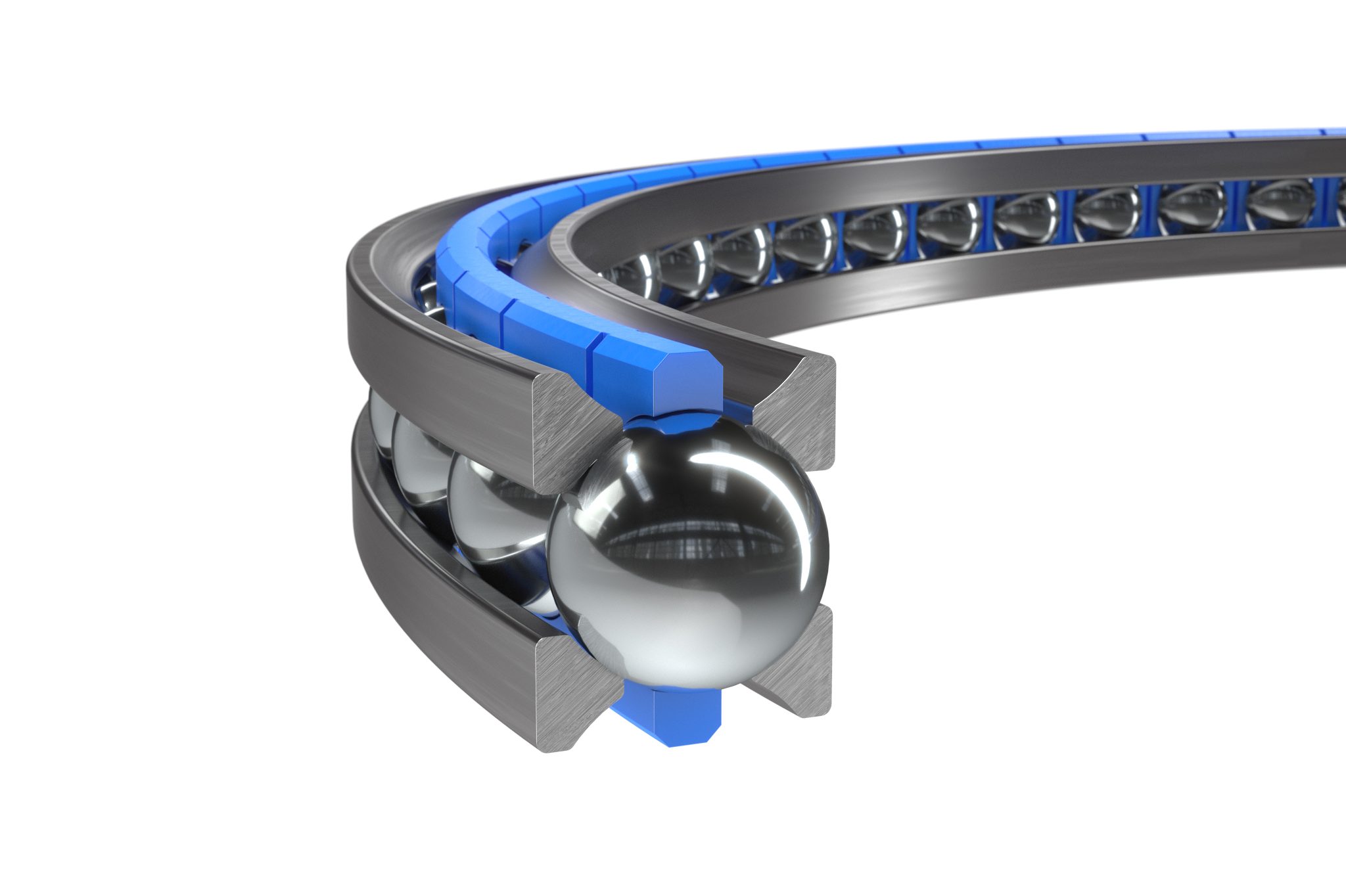

• 4 race rings with profiled raceways

• Plastic ball cage with retained balls

• Franke bearing elements in type LER are designed for medium rotational speeds and accuracies. They run smoothly, possess high dynamism and require just compact mounting space. The straight contact surface ensures simple integration in the mating structure and also a high rigidity. The attractive price makes this bearing element type LER an economic solution.

Characteristics

• Maximum possible integration capacity

• Series application to meet cost constraints

• Greatest possible flexibility of preload, runability and diameter ranges

• Bearing elements of the LER type consist of two inner and two outer raceways, along with a plastic cage with retained balls. The race rings are divided at one point to compensate for the temperature expansion factor. They possess compensatory properties for demanding forms of stress. LER are generally mounted free from clearance. The preload can be defined individually to meet the specific requirement.

Diameter Range

Infinitely variable from 70 to 2000 mm

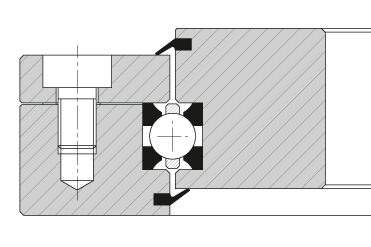

Mating structure

The bearing element mounted determines the overall con- struction’s load bearing capacity. Hence the mating con- struction can be made of alternative materials such as steel, aluminium or plastic. Axial and radial accuracy (see diagram on left) are defined to a substantial extent by the mating components. These properties can be enhanced by boosting the accuracy of manufacture.

Technical Details

• Material: Ball race rings: 54SiCr6, rolling element: 100Cr6, cage: PA12

• Temperature in use: –30 °C to +80 °C, briefly up to +100 °C

• Circumferential speed: max. 5 m/s, without seals max. 10 m/s

• Lubricant grease: Klüber Isoflex Topas NCA52

• Lubricant schedule: Contact us for further information

•Tolerance details: Contact us for further information

For additional information on bearing selection, calculation, mounting and setting contact us.

Types of Bearing Elements

LEL Ground Raceways

• 4 Race rings with ground raceways

• Plastic ball cage with retained balls

• Meet high standards in terms of runnability and accuracy

• Hardened and CNC-ground raceways, along with the ideal geometric adjustment of ball and raceway radius, lend them outstanding bearing properties

• Permits the greatest possible freedom of bearing design

• The standard mounting space is between 5.9 mm and 20.9 mm

• Race ring thickness of up to 20 mm and bearing sizes up to 50 mm are possible to meet special requirements

LER Rectangular Profile

• 4 race rings with profiled raceways

• Plastic ball cage with retained balls

• Designed for medium rotational speeds and accuracies

• Run smoothly, possess high dynamism and require just compact mounting space

• Straight contact surface ensures simple integration in the mating structure and also a high rigidity

LEW Cross Roller Bearing

• 4 race rings with ground raceways

• Plastic cage with rollers

• Suitable for medium rotary speeds and accuracies

• Smooth running, high stiffness and compact installation space.

• Crosswise arranged rollers absorb the same high loads from all directions.

• Robust and insensitive to shocks and vibrations.

Contact us

For more information or a no obligation quote please get in touch below.

EXPERIENCE

With a collective knowledge and experience of over 30 years in engineering industry, we work to adapt, create and innovate, to enable us to deliver bespoke engineering solutions to meet your requirements.

DESIGN, MANUFACTURE, STOCK & SUPPLY

From our Lancashire headquarters we offer a one stop shop for all your linear and rotary requirements for both existing applications and new product innovations.

SITE ASSESSMENT, INSTALLATION & FITTING

As a privately owned business we have the flexibility to offer an industry unique full turnkey package to engineers. From site assessment, installation through to fitting.